Bottle washing & steam sterilising

Practical Action

Bottle sterilisation

It is well worth considering the

steam sterilisation of bottles as a

final precaution prior to filling.

This is particularly true if a hot

filling system is to be used. Glass

sometimes contains flaws and the

hot filling of a cold container can

cause it to shatter. This results in

splinters getting in the product and

represents a total loss of product.

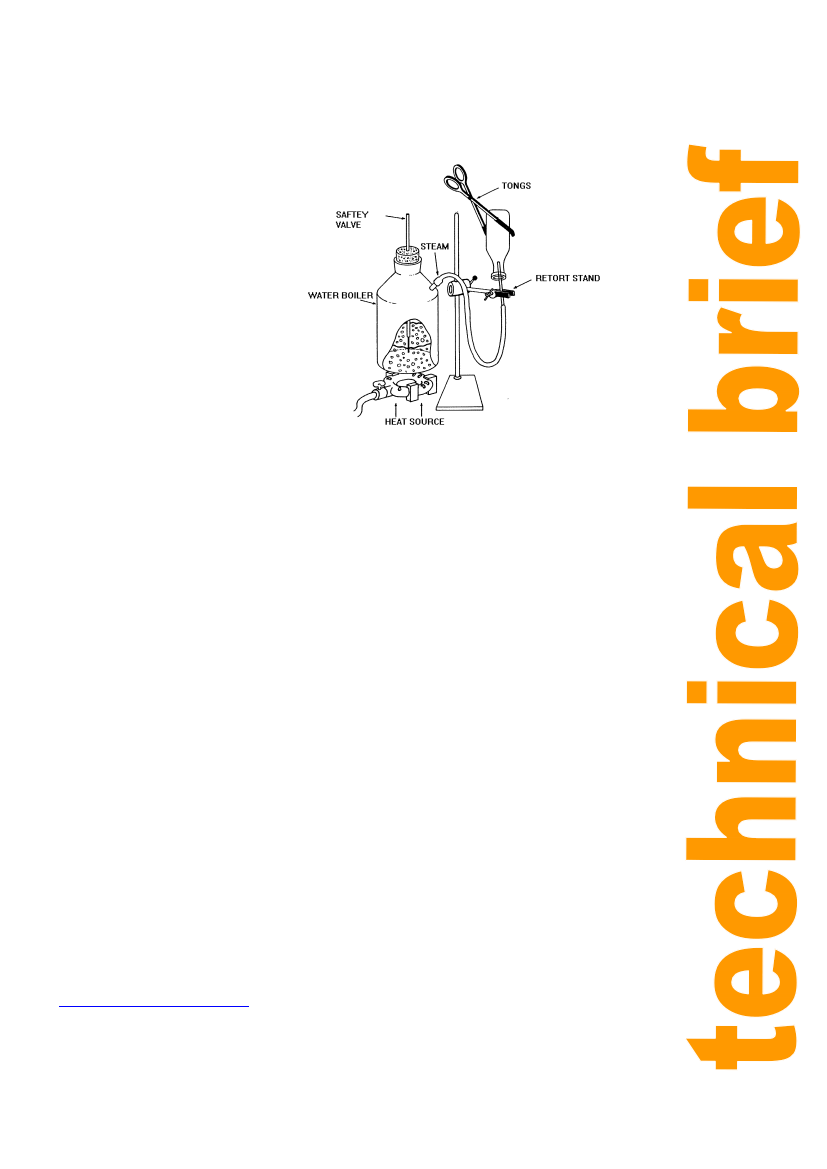

A simple bottle steamer can easily

be made by a tinsmith from copper

or brass sheet, see Figure 4. It

should be noted that the vertical

safety tube is absolutely essential.

In use, the washed bottle is inverted

over the steam spigot for 15 to 30

seconds until steam emerges from Figure 4: A simple bottle steamer

its neck. Obviously, the use of

protective gloves and tongs will be

necessary to handle the hot glassware. It is also strongly recommended that the operator carrying

out the steaming should be required to wear safety goggles as occasionally there will be breakages.

Additionally, some form of simple screen between the bottle steaming point and the filling point is

recommended.

Equipment suppliers

Bottle Washing Equipment

Gardners Corporation

6 Doctors Lane

Near Gole Market

P. O. Box 299

New Delhi – 110-001

India

Tel: +91 (0)11 2334 4287 / 2336 3640

Fax: +91 (0)11 2684 1886

Techno Equipments

Saraswati Sadan

1st Floor

31 Parekh Street

Mumbai – 400 004

India

Tel: +91 (0)22 2385 1258

Eastend Engineering Company

173/1/ Gopal Lal Tagore Road

Baranagar

Calcutta 700 036

India

Tel: +91 (0)33 2577 6324

Fax: +91 (0)33 2556 6710/160

Useful websites

Search database of packaging product suppliers

http://www.packagingindia.com

2